ProductsContact Us

National free service hotline: 400-993-0731 Email: tjs@haozhigroup.com |

Product Details

Current Position:

Home>

Product Details

China is at the peak of its construction. Nearly 2 billion square meters of houses are built each year, and only about 10 % of buildings can meet the National energy conservation standards. Of the about 40 billion square meters of buildings that are available, more than 95 % are energy-intensive buildings. It is urgent to implement energy-saving buildings in China. The most direct factor affecting building energy consumption is the insulation and insulation performance of the building maintenance structure, and doors and windows are the weakest links. According to statistics, the energy consumption of window and window glass in the building accounts for about 35 % of the total energy consumption of the building. Especially in summer, sunlight brings huge heat into the interior through glass doors and Windows, which makes the energy consumption of air conditioning significantly increase. With the increasing demand for energy conservation in buildings around the world, our government is playing an even more important role in improving energy conservation in buildings. And to the window glass affixed high permeability and high heat insulation nanometer energy saving film is the most saving, saving, saving energy and reforming measures. Water-coated nanometer energy conservation film saves 30 % of cooling energy consumption in summer and 15 % of heating energy consumption in winter.

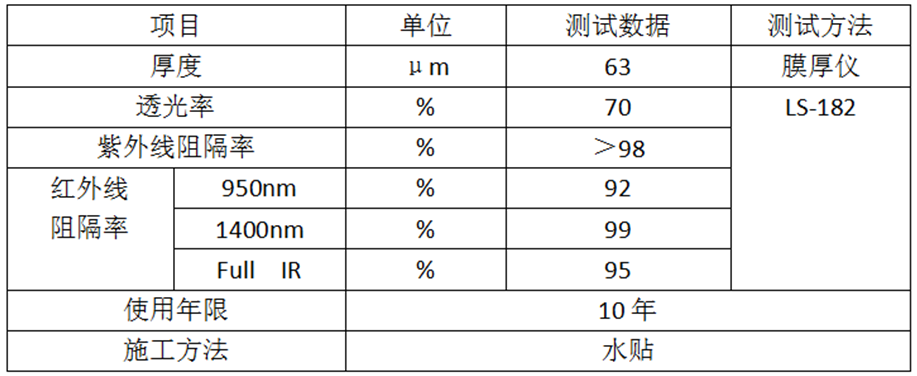

Product principle: Sunlight energy is divided into three parts: ultraviolet(invisible light) energy accounts for 3 %, visible light energy accounts for 43 %, and infrared(invisible light) energy accounts for 54 %. In order to reduce the amount of heat that sunlight brings into the room without affecting indoor lighting, the ideal state is to ensure that most of the visible light enters the room while blocking the entry of ultraviolet and infrared rays. Nanoceramic thermal insulation film is based on PET treated with surface hardening, using nanometer multi-doped oxide with excellent thermal insulation as the medium, and using unique dispersion technology to treat the ink. Then the precision coating process is processed to form a functional film that can be directly glued. Insulation principle: Nanoceramic particles can absorb very strongly near infrared and far infrared, but have a high permeability to visible light, converting infrared light into heat, because(1) the heat transfer coefficient of glass is much greater than that of PET(2) Outdoor air is convective, Helps to disperse heat. Therefore, most of the heat absorbed by infrared radiation spreads outdoors, and only a small amount of heat(<UNK> 10 %) radiates to the interior at a distance of infrared radiation, which can reduce the indoor temperature by 5-8 °C. Product features: High thermal insulation: At 70 %, the infrared resistance can reach 95 %; The indoor temperature is reduced by 5 °C -8 °C. Ultraviolet barrier: the addition of a highly effective ultraviolet absorber, can shield more than 99 % of ultraviolet light. Non-oxidation: 100 % metal-free, durable, non-oxidizing. Imfading: Use the inherent color of the ceramic without adding any pigments, so the ceramic insulation film will never fade like stained metal. High durability: in the service life, ceramic insulation film shelf life is 10 years, magnetron sputtering film generally 5 years Safety: Avoid safety hazards caused by broken glass. Product parameters:

Product application: Building doors and Windows, outdoor ceiling, car front block, side rear block, train, aircraft window, cruise ship and so on. Next

|